The Biggest Fan of Trump’s Steel Tariffs Is Suing Over Them

JSW Steel’s billion-dollar plan for Making American Steel Great Again depended on tariff exemptions. Two years later, they haven’t materialized.

John Hritz, president and chief executive officer of JSW Steel USA Inc., put on a big smile and a Texas flag pin for his television spot on Fox Business in March 2018. “It’s a special day,” he told his host, then told her again: “It’s a special day.” JSW Steel’s India-based parent company, JSW Group, had announced it would invest $500 million and create 500 jobs at its steel mill in Baytown, Texas. “We’re going to make history,” Hritz said.

Hritz was counting on help from President Trump, who three weeks earlier had announced his intention to impose tariffs of 25% on steel and 10% on aluminum imported to the U.S. The Fox anchor wondered if the import levies might interfere with JSW’s Baytown plan, given that much of the raw steel processed at the mill was imported from India and Mexico. “Absolutely not,” Hritz said. On the tariffs, JSW was “in lockstep with the president and with the administration.”

Not so much anymore. A big piece of the Baytown project has been postponed indefinitely, in part because of Trump’s tariffs. Both Baytown and a sister plant in Ohio, where JSW once planned to invest another $500 million, have been operating at unprofitably low production levels, also owing in part to the tariffs. JSW has sued the administration for refusing to exempt it from paying the levies on the massive slabs of steel the company imports and turns into pipe and other products for industrial use. “It’s the hypocritical nature of these tariffs that’s completely dumbfounding us,” says Parth Jindal, director of JSW Steel USA and managing director of JSW Cement Ltd. in India. “It just doesn’t add up.”

As Hritz sees it, JSW set out two years ago to do precisely what Trump and his trade hawks said the tariffs would help accomplish: reestablish the U.S. as a premier producer of steel. Hritz told the online trade publication Fastmarkets AMM after the tariffs were put in place, “We are following right down the road where the administration wants things to go … to completely overhaul the steel industry in this country.” But the revolution has been delayed by a bureaucratic morass at the U.S. Department of Commerce and, possibly, political weight thrown around by two of steel’s heaviest heavies: United States Steel Corp. and Nucor Corp.

Other steel processors are in a position similar to JSW’s, paying tariffs on raw steel they say they can’t procure here. NLMK, the U.S. arm of Russia’s Novolipetsk Steel PJSC, has had rolling layoffs at a plant in Pennsylvania because it’s been paying tariffs on slab from Russia—$184 million and counting, says Robert Miller, NLMK’s U.S. CEO and president. “That frustrates me because now you’ve affected people’s families,” he says. “We’re an American company with American workers represented by American unions. That’s what sucks.”

Even before the Trump tariffs, domestic steelmakers enjoyed ample government protection, via scores of duties imposed on companies or countries judged by the Commerce Department to have dumped steel in the U.S.—that is, sold it below cost—or otherwise violated trade laws. The new tariffs had a salutary effect for a while: Steel prices rose, and U.S. Steel and others reactivated mills. Then U.S. manufacturing went into a recession, and prices fell. Some steelmakers are retrenching. U.S. Steel recently said it would cut capital spending and close most of a plant near Detroit, costing about 1,500 jobs. All told, U.S. iron and steel jobs are up 3%, or 2,600 workers. That gain would be more than halved by the U.S. Steel cuts.

JSW’s experience of the tariff wars is peculiar not only because the company energetically backed the tariffs. Hritz continues to praise the administration even while battling the Commerce Department in court. The whole situation is an awkward lesson in unintended consequences—it makes you wonder whether, when it comes to trade policy, some capitalists really don’t like capitalism that much.

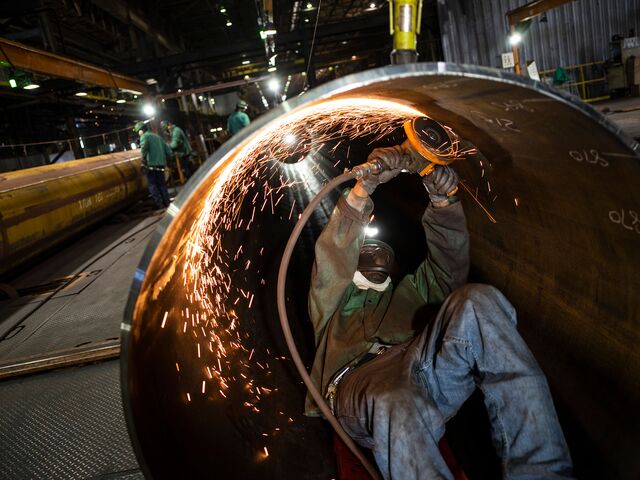

A two-lane asphalt road burrows through trees and tall brush to JSW’s Baytown plant, about 30 miles east of Houston. The complex squats on the grassy tip of a peninsula that’s also home to some of the world’s largest petrochemical facilities and huge warehouses owned by Walmart, Ikea, and Home Depot.

Hritz, a short, stocky 65-year-old who wears his brown hair shaggy, started his four-decade career as an apprentice craftsman at a U.S. Steel plant in Youngstown, Ohio. He calls himself “an equipment guy” and gets excited showing visitors a slideshow of machinery being installed at Baytown. “Look at those beautiful double-side and end shears—they’re already on-site,” he says, referring to machines that cut slabs of steel like gigantic meat slicers. One slide in the presentation boasts that JSW is “Making American Steel Great Again.”

U.S. Steel opened Baytown in 1970 and employed as many as 2,000 workers there before closing it in the 1980s. By then, the long decline of the American steel industry was under way. Hritz witnessed it firsthand in Youngstown in 1980, when his employer closed the Ohio Works plant, killing thousands of jobs. The Baytown facility, which JSW bought in 2007, is now a rerolling operation. Rerollers import what’s known in the industry as semifinished steel, often in slab form, and process it into finished products such as pipes, as well as into sheets and plates that customers shape into auto body panels, washing machine shells, and other things. In Baytown, JSW’s largest customers are energy companies, for which it fabricates pipes that channel oil and gas across Texas and the Great Plains.

Importing semifinished slabs gives rerollers a slight cost advantage over U.S. Steel and other fully integrated steelmakers, which use expensive blast furnaces to convert iron ore into usable steel. But rerollers remain more costly than minimills such as those operated by Nucor, which uses electric-arc furnaces to forge raw material from scrap metal and has little need to buy from overseas.

In a 2001 case that foreshadowed the debate over the current steel tariffs, the Commerce Department studied whether imports of semifinished steel might pose a threat to U.S. national security, given that easy access to steel would be crucial in the event of war. The so-called Section 232 inquiry was conducted under a 1962 trade law that empowered the president to impose levies on imports of products deemed vital to national security.

Commerce concluded that semifinished slab imports were no such menace, mainly because traditional U.S. steelmakers already produced three times the semifinished steel that might be needed in a conflict. The traditional companies used most of that internally to fashion products for customers and sold little of it to rerollers and other rivals. A study from Rutgers University in 2003 said the traditional companies had scant incentive to sell the stuff to their domestic competition, because they could reap bigger profit margins making it into customer products.

None of that mattered much to Jindal, whose father, Sajjan Jindal, is chairman of JSW Group, which owns a giant Indian steelmaker as well as major energy and infrastructure businesses. Starting around 2009, the younger Jindal, then an undergraduate at Brown University, visited Baytown during semester breaks. The plant was unprofitable, which he saw as an opportunity for both his father’s company and himself. “I became emotionally attached,” he says. “If I could turn it around, it would be a huge boost to my credibility. I wouldn’t just be viewed as the father’s son.”

Much of Baytown’s decades-old equipment was prone to costly breakdowns. Customers returned significant amounts of products because of poor quality. Only three energy companies had approved the plant as a regular supplier. Jindal and the bosses in India decided they had to dump the place or spend a pile of money on upgrades. They chose the latter option, reasoning that Baytown would be a big test of its ability to expand outside India.

Jindal was working on his MBA at Harvard in 2014 when he had a three-hour dinner in Boston with Hritz. An attorney, electrical engineer, and seasoned executive with experience at AK Steel Corp. and several other steel companies, Hritz was eager to try to turn around Baytown. In early 2015, JSW named him CEO of its U.S. operations.

The parent company was dangling serious investment, but first Hritz had to show he could get Baytown into the black. To give the old machines periodic chances to rest, he went to four days on and three days off, which also helped cut overtime costs. He instituted stringent quality and safety processes. The customer rejection rate declined, and more energy companies endorsed JSW as a supplier of pipe. (Today, as many as 38, Hritz says.) Hritz himself went customer to customer asserting that JSW was a different company than before. The plant started to make money.

Hritz was fired up, even more so after Trump was elected. JSW by then was laying the groundwork for the plan to build Baytown an electric-arc furnace along with a slab-casting machine that would spit out steel slabs for products to feed the fracking boom in Texas’ Permian Basin as well as an expected upswing in infrastructure spending. (The latter has yet to materialize.) Once the arc furnace was running in a couple of years, Baytown would no longer have to import slab; the new furnace and caster would supply it.

Domestic steelmakers helped persuade the Commerce Department in 2017 to revisit the question of whether steel imports threatened national security. This time the answer was yes. Since the 2001 study, imports had risen to more than 30% of U.S. steel consumption, the department said. The number of facilities operating blast furnaces had fallen to nine, from 19, and the industry had been operating for years in the red. Domestic makers “will be unable to meet the current and projected needs of the U.S. military and critical infrastructure sectors,” the department concluded on Jan. 11, 2018.

Trump announced his intention to impose the tariffs on March 1, 2018, and a week later it was official. Hritz was delighted. He expected the levies to discourage foreign rivals from illegally dumping steel in the U.S. while JSW built out Baytown. (JSW units in India were found to have been illegally dumping cold-rolled and coated steel in the U.S. in 2016; the company says it’s since stopped shipping it.)

Jindal says he thought the Trump tariffs “were just going to make our strategy the correct one.” JSW announced its Baytown expansion plan on March 26, 2018. A few days later the company acquired an old Wheeling Pittsburgh Steel mill in Mingo Junction, Ohio, for $187 million. It vowed to reactivate the plant’s idled electric-arc furnace and add a new one, at a cost of $500 million. JSW would have three arc furnaces in the U.S. (Nucor has 28.)

Steel Employment and Production

Data: Bureau of Labor Statistics, American Iron and Steel Institute

Mingo Junction was a risky play. Set in a scruffy hill town where scenes from The Deer Hunter were shot, the mill dated to the late 1800s, and a series of previous owners had failed to make it work. Weeds were growing through some of the ancient machinery. Undaunted, JSW revived the existing arc furnace while making plans for the new one. Jindal envisioned the mill serving the auto and construction sectors while Baytown focused on energy. Mingo Junction Mayor Ed Fithen declared, “I always knew something would happen. I never lost faith.”

There was a problem, though. Buried in the Commerce Department analysis was a time bomb for JSW and other rerollers: Semifinished slab steel was lumped in with all the other steel being shipped from abroad, and therefore would be subject to tariffs. The department said affected companies could remedy this by seeking exclusions from the tariffs. Petitioners needed merely to demonstrate that the stuff they were importing wasn’t readily available in the U.S. Requests would be decided, Commerce said, “in general … within 90 days of a completed application being filed with the Secretary.” JSW had to wait a year.

The same day news of the Mingo Junction deal broke, Jindal and Hritz met with Secretary of Commerce Wilbur Ross in Washington. Jindal says Ross was pleased about JSW’s plan to invest $1 billion in the U.S. While not guaranteeing anything, “he said, ‘We will look at your tariff request very favorably,’ ” Jindal recalls. A department spokesman, without commenting specifically on any meeting, says exclusion decisions are made solely on publicly available information submitted by interested parties.

The department was unprepared for the flood of requests it got for exclusions. It had estimated there would be 4,500 petitions for tariff relief. By early 2019 it had more than 50,000 from steel and aluminum makers, as well as from manufacturers of furnaces, razor blades, automobiles, and other metal goods, according to an analysis by the Mercatus Center, a research think tank at George Mason University. As of late January, steel claims alone had risen to more than 141,000, with almost 75,000 granted, 22,000 denied, and 27,000 rejected for filing errors, according to the Commerce Department.

JSW filed six exclusion requests for imports from India in April 2018, followed by another six for Mexican imports that June. JSW told Commerce it couldn’t rely on “direct competitors” in the U.S. to supply its slab. Echoing the department’s 2001 analysis, JSW said that the material it needed simply wasn’t available in the quantities and specifications it required and that, furthermore, competitors had no incentive to sell JSW slab that they could process and sell themselves at a higher markup.

JSW told the department it needed to import slab only during the two years necessary to complete the Baytown expansion. Lacking relief, the company said, “JSW will be unable to continue operating the Baytown plant on an economic basis.” Publicly, Hritz expressed confidence that the tariffs would bolster the domestic industry. “People that are complaining about the Trump administration, let them complain,” he told Fastmarkets AMM in June 2018.

Months passed. Two different parts of Commerce were studying petitions from scores of companies, and Congress requested tweaks to the process that temporarily slowed things. The department spokesman says the creation of an online portal last June for exemption pleas means there are “essentially zero requests” that aren’t being “meticulously” considered.

Complicating matters, some steel companies submitted objections insisting they could supply whatever steel was needed, so those seeking tariff relief didn’t deserve it. In other words, if Company A seeks to avoid paying tariffs on steel from Brazil, Company B can object by asserting that it can deliver the same steel within eight weeks. Objecting to one of JSW’s exclusion pleas, Nucor asserted that giving slab production to American mills—such as one U.S. Steel was restarting in Fairfield, Ala.—is “exactly the outcome intended” by the tariffs.

That’s true, if the objecting company is painting an accurate picture. But as Christine McDaniel, a senior research fellow at the Mercatus Center, says, “You don’t have to prove that you can make it for me, you just have to say that you can.” That can result in some problematic arithmetic. For instance, Nucor, which produced 24.4 million metric tons of steel in 2017, has told Commerce it could supply 42 million metric tons to companies seeking tariff waivers, according to Mercatus. U.S. Steel said it could produce 49 million metric tons for its competitors, more than three times its production in 2017.

McDaniel says Nucor and U.S. Steel appear to have leveraged their political ties to Trump, who campaigned hard in Ohio, Pennsylvania, and other steel states on reviving the industry. In October the Commerce Department’s inspector general, without naming names, issued a memo saying that a “lack of transparency” had contributed to “the appearance of improper influence” and that Commerce officials “may not be impartial” in making tariff exclusion decisions. The department says it’s “taken numerous steps to safeguard the Section 232 exclusion process” and plans to “further improve transparency with industry.”

U.S. Steel declined to comment. Nucor spokeswoman Katherine Miller noted that companies seeking tariff relief have requested exemptions on more than 107 million tons of steel—at least triple the amount of all 2018 steel imports, rendering Mercatus’s arguments “meaningless.” Former Nucor CEO Dan DiMicco, who advised the Trump campaign on trade, says of JSW, “I give them credit for where they’re going, but they could have done this years ago, and they didn’t.”

JSW’s waiver requests faced objections from Nucor, U.S. Steel, and AK Steel. JSW’s Washington lobbyists at the Vogel Group repeatedly met with Commerce officials to point out that the objectors couldn’t possibly meet the company’s needs. In April and May, the department nevertheless issued two batches of almost identical denials, saying U.S. companies produced the slab JSW needed in “a sufficient and reasonably available amount” of “satisfactory quality.” JSW has now paid about $50 million in tariffs.

On July 25, Hritz and a Mingo Junction worker joined a large group that gathered with Trump at the White House to mark the anniversary of a pledge for U.S. businesses to create more jobs. Hritz praised Trump’s “bold leadership on tax reform, a smart regulatory agenda, and investing in American workers.” Five days later, JSW sued the administration in the U.S. Court of International Trade.

Hritz’s office at Mingo Junction is in a sparsely furnished trailer with a view of the Ohio River. To use the restroom, he has to go outside to an adjacent building.

Parts of the mill itself feel like a steel industry museum. Much of the floor is dirt. Large areas are strewn with unused parts waiting to be scrapped. But there’s also the newly living arc furnace as well as stacks and stacks of steel slabs, heat still rising off them days after they were made.

Mingo Junction and Baytown are both losing money “hand over fist” when the tariffs are accounted for, Jindal says. The mills are operating at well below 50% capacity, when about 70% is necessary to turn a profit. JSW has indefinitely postponed plans to build the arc furnace at Baytown and add the second at Mingo Junction. Although the company has added several hundred workers at the facilities, it recently laid off 175 at Baytown, and total investment in the two plants is expected to be closer to $350 million than the original $1 billion, Jindal says.

These problems aren’t all a result of having to pay tariffs. JSW has had to slow production at Baytown while installing new equipment. In addition, a number of steelmakers reactivated furnaces as prices for steel rose for a while after the Trump decision. The increased supply eventually caught up with decreasing demand, pushing down prices and contributing to the recent layoffs at U.S. Steel.

Like NLMK and other rerollers, JSW has rejiggered its supply chain to source slab from countries exempt from tariffs. But it’s a game of industrial whack-a-mole when Trump can change things with a tweet, as he did in December by unexpectedly declaring Brazil and Argentina no longer exempt from the levies. He reversed himself on Brazil and hasn’t followed through with action on Argentina.

If Hritz is discouraged, it’s hard to tell. He says he’s confident that JSW’s lawsuit will eventually work in its favor, the government will refund the tariffs, and the company will become a bona fide melt-and-manufacture operation. “We want to have our tariff money back, and then we can go faster,” he says. “When we’re all done, we’ll have one hell of a steel company.”